TL494 Ultimate Adjustable Power Supply Circuit (SMPS) 0-50V 0-15Amps 750WattS!

TL494 Ultimate Adjustable Power Supply Circuit (SMPS) 0-50V 0-15Amps 750WattS!

TL494 Adjustable Switch Mode Power Supply Circuit Overview

|

| TL494 adjustable power supply Circuit electrobuff.blogspot.com |

For every electronics hobbyist, a proper power supply is a must. This is basically a DIY bench power supply which you can easily make at home by salvaging components around from electronics junk. It provides adjustable regulated DC voltage between 1.5V - 50V, and short-circuit protection which kicks in at 15A. An all-around bench supply in other words.

The circuit operation is pretty straight-forward, and very modifiable. The output voltage is compared with a stable reference voltage, and based on the error the TL494 adjusts the duty cycle to compensate. The output from the TL494 drives a BJT full-bridge, which drives the gate drive transformer (GDT).

The GDT controls the IRFP450 power Mosfets. The IRFP450s are in a half-bridge configuration and run the main power transformer at the duty cycle decided by the TL494 chip. The output from the main power transformer is rectified and filtered, and finally the output voltage is measured again by the TL494. This is called closed-loop operation.

PWM Generation and Overcurrent detection Section

In my experience the logic section with GDT and fan(s) consumes about 15W +/- 5W. Keep this in mind when looking for a small 16V power source. Iron-cored wall warts work well for this purpose. Pin 14 on the TL494 generates a regulated 5V output, which is used for providing a stable reference voltage. I do not use it for the 5V source in the comparator section, as I don't want to load it down.

One of the error amps on the TL494 is used to determine the duty cycle. The reference is divided by 2 with two 15k resistors and fed to pin 2 giving a 2.5V reference. The output voltage from the supply is sent through a divider as well, and depending on the potentiometer setting will provide an output voltage of 2.5V at different voltages (1.5-50V). With low resistance the ratio is low and it only takes 15V before the divider output is 2.5V, high potentiometer resistance results in a large ratio and high voltage required before 2.5v is reached.

From pin 3 to pin 2 is a gain compensation network, consisting of a capacitor and resistor. The purpose of this is to stabilize the control loop, and it's design is far too complex to explain in this blog. All you need to know is that the capacitor's impedance will vary with frequency, in effect giving a frequency dependent resistor. This coupled with the 180k resistor gives the error amp frequency dependent gain, allowing for stabilization depending on the load, duty cycle and frequency.

The overcurrent detection works by sensing current with a shunt resistor, which is a resistor from your load to real/circuit ground. Thanks to Ohm's Law (U=R*I <--this is too easy) we know that with a set current and resistance, the voltage developed across the resistor is known. Just a note to the circuit, power ground is the negative lead out from your supply, you can't use ground as the negative supply lead if you want overcurrent protection. The voltage developed across the resistor is fed through an RC filter which slows it down and keeps the mean value, and later amplified by the first op-amp. Amplification reduces the voltage needed across the resistor, which greatly reduces it's losses. The gain of the first op-amp is set with the 3 resistors around it (39k, 2.2k and 100R) and depending on the gain different overcurrent levels can be chosen. The second op-amp acts as a comparator and trips the small SCR when the current limit is exceeded, lighting the warning LED at the same time. Just like with the TL494 error amp you set a reference voltage on the inverting input with a voltage divider, and feed the signal into the non-inverting input. The funky dual LED will light one of it's didoes when an overcurrent condition occurs, while the other diode will lose power since it's powered from the main supply.

Gate Drive Transformer Section

The output section in the TL494 consists of two transistors, which cannot drive a transformer directly. So by using some pull-up resistors it can drive a full-bridge of small BJTs, which can then drive a GDT. The design of the full bridge and TL494 outputs is such that during deadtime both primary leads of the GDT will be held low. This is equivalent to shorting the core, which resets it and allows for flawless duty cycle generation through a transformer. Toroidal ferrite cores with high Al value and decent cross-sectional area (50-100mm^2) are excellent for GDT creation. At low frequency operation such as this quite a few turns are required. Although the voltage stand-off isn't optimal, and some cores are sharp enough to scratch off enamel I've used magnet wire for winding my GDT. In high frequency applications I use multi-strand coax cable, which gives the best performance. See how you feel about the core and safety when you choose materials.

POWER Section

Rectified mains is filtered (this is optional) mainly to keep noise from the supply from traveling back up mains and disturbing other appliances. I built an unregulated and sloppy SMPS for an amplifier before this project, without a filter of course, and whenever I turned it on my brother's amplifier in another room would start humming. So yes, it is somewhat important. Mains is rectified with a beefy bridge and filtered with a large storage capacitor. Between the bridge and capacitor is a NTC. NTCs have a negative thermal coefficient, hence the name. What they do is have low resistance at high temperature, and high resistance at low temp. In this circuit one is used to limit the inrush current to the man filter capacitor. Since a large capacitor will provide a substantial load when empty, it can draw enough current when starting up the PSU to blow fuses or a breaker. The NTC prevents this by limiting the initial current, and slowly letting more through as it heats up. The problem is that when drawing 500W or more large NTCs are needed which aren't easy to find or very practical, so the NTC can be omitted. If the filter capacitor causes your breaker to trip use a light-bulb/switch like in my MKII multipurpose inverter. The two 120k resistors simply bleed away charge on the filter capacitor when the supply is turned off.

From the GDT outputs come alternating square-wave pulses 180 degrees out of phase, which control the IRFP450s. Together with the two 3µF capacitors they form a half-bridge, which sends alternating current through the main power transformer. The two 3µF capacitors will carry all of the load current, and should be polypropylene foil type capacitors. Some designs use electrolytics for the half-bridge and filter capacitors in one, but I've found that the electrolytic heat up and eventually fail when used this way. The amount of average current sent through the transformer is controlled by the duty cycle, which is controlled by the TL494. The secondary is center-tapped so dual diode rectification can be use. For filtration of the rectified output a 33µH inductor and 1000µF capacitor are used. The double 400V 16A rectifiers seem to be overkill, but I found them necessary. They were reasonably cheap anyway. Experiments with 60V Schottky diodes resulted in plenty of failures for some unknown reason, so I would go no lower than 100V, and rate the diodes generously for the current. This is your workhorse remember!

The power transformer itself was put together from an old ATX core, which is ideal since they are used in this exact same fashion and frequency. They might not be large enough for continuous operation at more than 300W, but enough to last shorter runs at twice that. A good question is how to design a transformer for 750W operation. What limits power in transformers is how much power they can dissipate. A core can lose power through losses tied to drive frequency and/or magnetic flux being too high, but that's about it unless I'm mistaken. The other losses are copper losses from the windings, and ideally you want to fill the entire window area with copper to reduce the resistance as much as possible. So if you can the required number of turns in at the required thickness in the winding area, the core is large enough. The resistance of the wires, even if only 0.5 ohms can drop a decent amount of voltage. Now the DC resistance might seem low, but remember that the skin effect kicks in too, increasing the effective AC resistance. At 45kHz, for 16A capable wire I would use four strands of 22AWG twisted together as litz wire. The primary only has to handle about 4-5A at full load, so bifilar 22AWG should be enough.

Watch my YouTube Video Tutorial

TL494 PWM IC Basics:

TL494 is a PWM controller integrated circuit that you can use for devices with power electronic circuits. It features two on-chip error amplifiers alongside an oscillator for adjusting frequencies, an output control circuit with feedback, and a flip-flop output with pulse steering control.

The error amplifiers are responsible for compensating voltage between -0.3 to VCC -2V in a standard voltage configuration. Also, the comparator dishes out almost a 5% range by controlling the dead-time with a fixed offset.

Further, the external oscillator provides a reference frequency signal for the PWM integrated circuit, while the Internal Regulator delivers a stable 5 V Reference Supply. However, you can always bypass the on-chip oscillator by attaching an RT to the output pin of the reference.

Interestingly, the TL494 is a complete PWM power-control circuitry that you can use for single-end operations. Also, the TL494 is useful for push & pull configurations.

TL494 Specifications

- The supply voltage ( Vcc) is up to 41 volts

- The maximum output current for both PWMs is 250mA

- Output voltage at collector pins is 41 volts

- It has a temperature range of -65 to 150 degrees

TL494 Features

- It has an in-built PWM control channel

- 200mA sink or source current

- It has dual output selectable operations, which include Single-ended and push-pull operation

- The TL494 has a variable range deadtime control feature

- You can easily synchronize the TL494 with other circuits

- It has two PWM outputs

- It comes with a fixed frequency oscillator

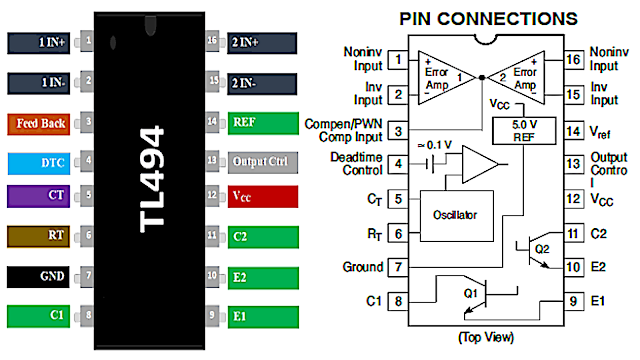

TL494 Pinout & Pin Configuration

|

| TL494 pinout electrobuff.blogspot.com |

|

| TL494 internal block diagram electrobuff.blogspot.com |

|

| TL494 block diagram guide electrobuff.blogspot.com |

| Pin Name | Pin NO. | Pin Description |

| 1IN+ | 1 | Noninverting input to error amplifier 1 |

| 1IN | 2 | Inverting input to error amplifier 1 |

| 2IN+ | 16 | Noninverting input to error amplifier 2 |

| 2IN- | 15 | Inverting input to error amplifier 2 |

| C1 | 8 | The collector terminal of BJT output 1 |

| C2 | 11 | The collector terminal of BJT output 2 |

| CT | 5 | The capacitor terminal used to set the oscillator frequency |

| DTC | 4 | Dead-time control comparator input |

| E1 | 9 | The emitter terminal of BJT output 1 |

| E2 | 10 | The emitter terminal of BJT output 2 |

| FEEDBACK | 3 | Input pin for feedback |

| GND | 7 | Ground |

| OUTPUT CTRL | 13 | Selects single-ended/parallel output or push-pull operation |

| REF | 14 | The 5-V reference regulator output |

| RT | 6 | The resistor terminal used to set the oscillator frequency |

| VCC | 12 | Positive Supply |

How does the TL494 PWM controller work?

As mentioned earlier, it is a fixed frequency and variable duty cycle dual PWM control circuit. It does not require any external components to operate except a few resistors and capacitors for an oscillator. This oscillator is responsible for generating a sawtooth waveform according to timing capacitor CT. This TL494 IC generates signals by comparing a sawtooth waveform with two control signals of the error amplifiers. The output signal will be on during the time when sawtooth voltage is greater than the voltage at error amplifiers outputs. You can see a block diagram given above.

- Output signal low: if sawtooth voltage less than the control signal voltage

- Output signal High: if sawtooth voltage greater than the control signal voltage

Pulse-Steering Flip-Flop transfers the PWM output signal to output transistors.

How to select TL494 Oscillator Frequency?

In the last section, we see that the oscillator is mainly responsible for generating sawtooth waveform. This sawtooth waveform used for deadtime control and PWM comparator amplifiers. Therefore, the frequency of the oscillator determines the frequency of output signals. Now, we will see how to choose the frequency of an oscillator.

We can select frequency by selecting suitable values of RT resistor and CT capacitor. We can select the capacitor and resistor values according to this formula:

Frequency= 1/ RT X CT

|

| TL494 Frequency calculation Formula electrobuff.blogspot.com |

TL494 Applications

- Switch Mode Power Supplies

- High Power Inverters

- Power Electronics Applications

- Power factor correction meters

- Desktop and Portable applications

TL494 Packages

This IC is available in four different 16 pin packages such as SOIC, PDIP, SOP, TSSOP. You can check the datasheet for the 2D physical dimension diagram of these packages.

TL494 Alternative PWM Controller ICs

The TL494's flexibility, ease of use, and reliable performance make it a preferred choice in various power electronics applications

Related Videos:

1. TL494 Adjustable Switching Power Supply for DIY Projects 1-120V 250W

Link: https://youtu.be/p-HBa85AdKw

2. TL494 2000W Power INVERTER with Modified Sine Wave Output

link: https://youtu.be/a-t2_5pSfcg

3. IR2153 Switching Power Supply 50-0-50V for Amplifier

link: https://youtu.be/b6Luryjd1jo

4. SG3525 Regulated Inverter 600W full Bridge

link: https://youtu.be/yipXbDlH0Z4

5. 5000W Inverter with IR2153 12V to 220V DC to AC

link: https://youtu.be/4nAQGTPSs0A

6. TL494 Modified Sine Wave Inverter

link: https://youtu.be/rFpdCwieseg

7. UC3842 Switch Mode Power Supply 3-15V at 10A

link: https://youtu.be/eTd_1wOxBr8

8. TL494 Adjustable Switch Mode Power Supply (DC DC boost smps) 1-50V 400W

link: https://youtu.be/bBgsszmleJY

9. TL494 Switching Power Supply for Power Amplifier 50-0-50V

link: https://youtu.be/fRnSoUzHnnE

10.TL494 Professional Voltage Booster 12-120V (DC DC boost converter)

.png)

.png)

.png)

Dear Sir,

ReplyDeleteVery well explained, both video and writeup.

Besides re-winding the transformer, what modifications would be required to increase the Voltage to 150V? I like to charge 10(ten) car batteries at a time.

I am learning SMPS working & design from your Video Tutorials.

Thanks in advance for your guidance & advice.

Charging ten car batteries( I assume they are lead acid chemistry) in series is a little bit tricky because of individual battery voltage balancing. I would recommend you rather charge them in parallel connection because then balancing of a few cells is way practical.

DeleteThe feedback network to the TL494 PWM IC from the secondary DC output of the SMPS is not isolated, so a 150V output would most certainly fry the controller IC together with the feedback network of the LM358 Op-Amp.

If you wanted a 150V output, you will need to obviously 10x the windings on the secondary side of the ferrite power transformer, plus you will need to use a voltage divider network feedback circuit before supplying the sensed voltage connection to the op amp.

This comment has been removed by the author.

Deletethanks for ur great videos.How can get the proteus file for simulation?

ReplyDelete